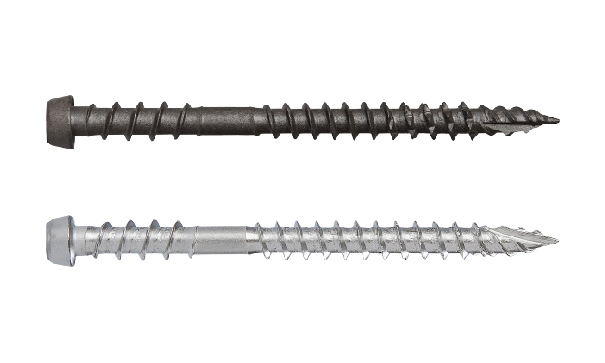

Composite/PVC/ACQ/Red Oak

● Category: Wood Screw

● Material: C1022, S.S. 305 high tensile available

● Size: #10 (M4.8)

● Length: 2-1/2” (63mm) or upon request

OEM/ODM is welcome

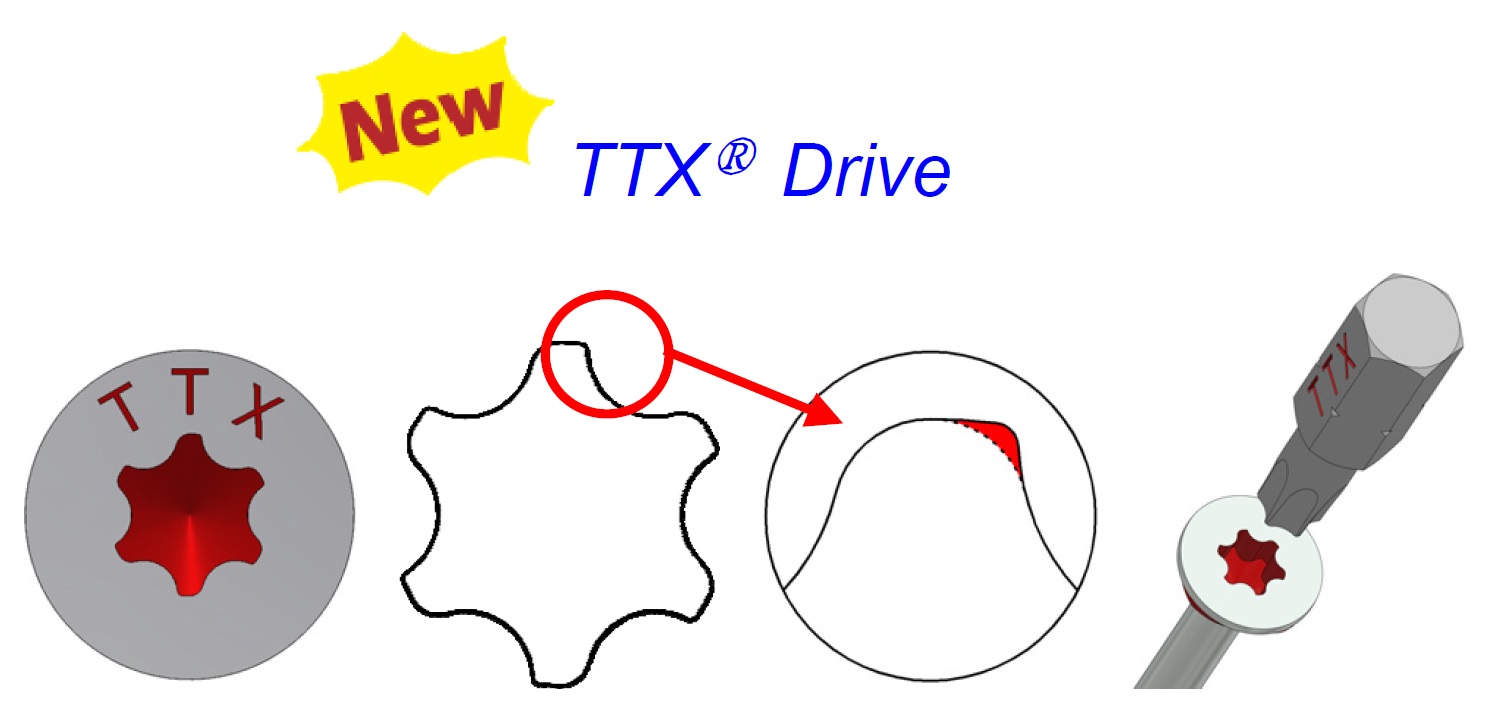

TTX® Drive

● Unique 6-lobe sharp hooks design, no cam-out

● More contact surface, less wear

● Superior bit engagement between TTX® drive and bit, higher torque transfer and no wobbling

● Universality:

TTX® bit fits all 6-lobe drives tight

All 6-lobe bits can fit TTX® drive

● Y2022 Fastener Innovation Awards in US

● Other drives are optional

● Patented: Taiwan, Japan, Europe, USA

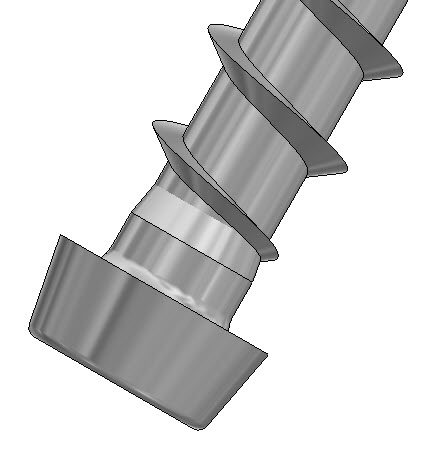

Cup Head

● Keep the object surface free of tailings and mushrooms around the screw head

● No splits on the surface close to the edge of object

● Small head keeps the surface smooth without wood splits after head sinking

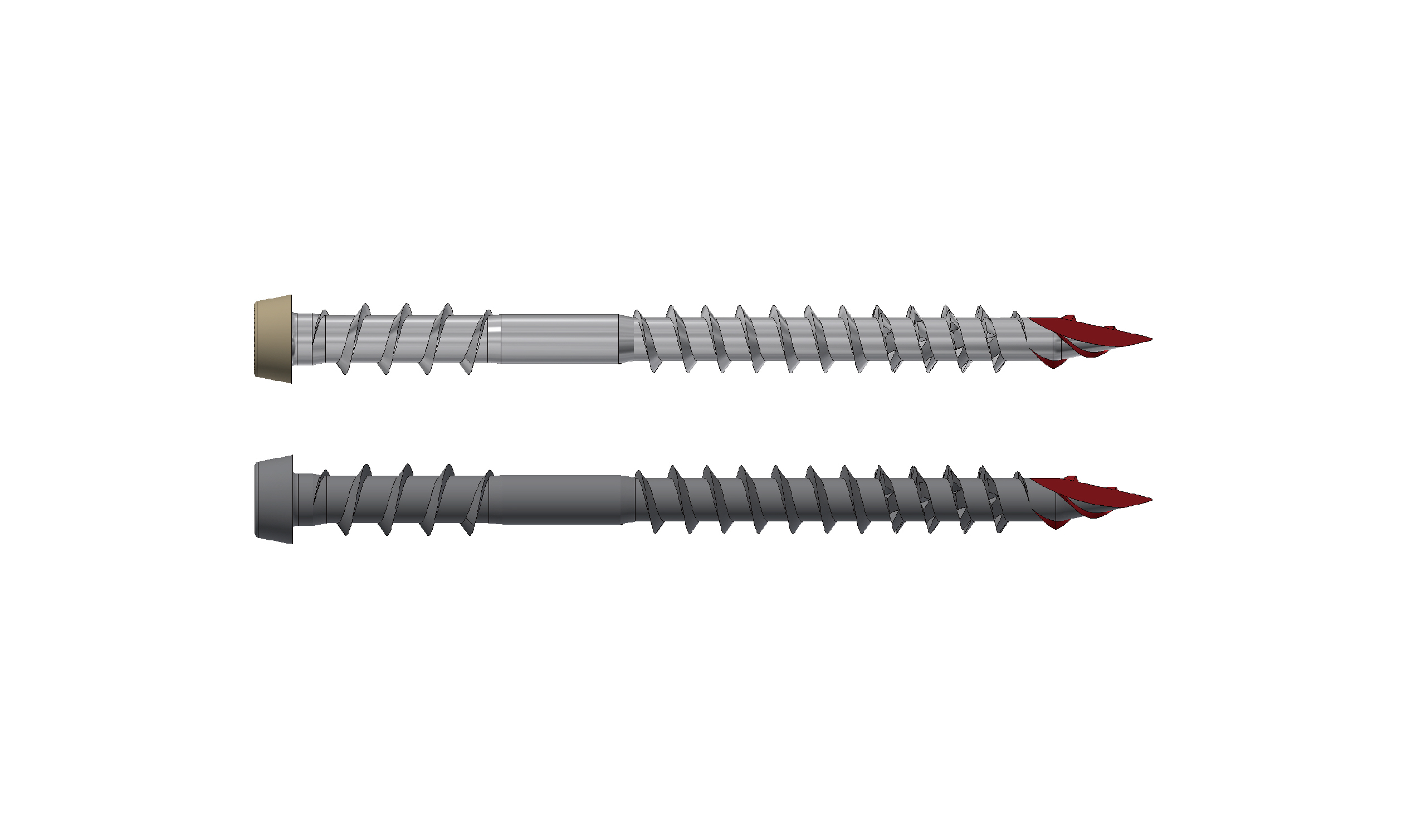

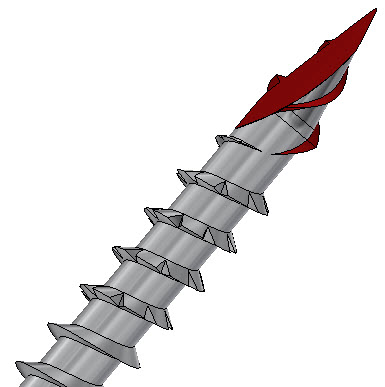

Torpedo Pre-milling Thread

● Immediately grabs onto soft/hard composite, solid core cellular PVC board, ACQ treated timber and Red Oak surface

● No split even close to the edge of soft/hard composite, solid core cellular PVC board, ACQ treated timber and Red Oak

● Low driving torque without wood splits, force-saving, reduction of the tiredness and the damage of hands

● Reverse thread prevents mushrooming and other surface defects

● Easily control the screw drilling direction without assisted device

● Long life KTCO® C4 Approved Coating protection or A2/A4 stainless steel available for real anti-corrosion purpose and is acceptable for use with ACQ lumber

● Possible to penetrate into thin steel sheet metal

KTX-Torpedo Plastic Decking Screw video

The best Plastic Decking Screw leads you to success.

FAQ

Q1: What is the application and applicable building material of KTX-Torpedo Plastic Decking Screw?

A1: KTX-Torpedo Plastic Decking Screw can be used on soft/hard composite, solid core cellular PVC board, ACQ treated timber and Red Oak deck boards.

Q2: Do you supply head painting on KTX-Torpedo Plastic Decking Screw?

A2: Yes, we can supply head printing on screws, and the MOQ of each screw is 300M. However, normally it is recommended to apply head painting on stainless steel screws. For carbon steel screws, we suggest adopting KTCO C4 Approved/KTX-Nano coating 2000HR, and the coating color can be customized.

Q3: What is the function of reverse thread?

A3: The reverse thread prevents mushrooming and other surface defects to create a beautiful appearance.

Q4: Can you provide the coating color matching the color of building material?

A4: Yes, please send your building material or pantone code to us for matching the color to avoid the color difference.

Q5: Besides coated screws, do you supply KTX-Torpedo Plastic Decking Screw in stainless steel material?

A5: Yes, we also supply SS302, SS304, SS305, SS305 high tensile and SS316 screws. The material depends on customer’s request. We can paint head on stainless steel screws to meet the color of deck boards.

-

Professional and Leading Screw Brand - KWANTEXEstablished in 1996Focus on Research and Design in fastener fieldSecond factory opened in 2015Industry 4.0 spirit

-

-

-

Strong R&D and QA TeamDevelop new products every yearObtain more than 100 patents3 major QA procedure:

Dimensional measurement

Mechanical properties test

Actual test on materialsEnvironmental lab:

Salt spray test and kesternich test -

-

- ISO 9001, ISO 14001, ISO 45001

- CE marking for EN 14566, EN 14592

- KTCO,Corrosion Protection Coating - C4 Approved by RISE in Sweden

- German Red Dot Product Design Award – KTX-Torpedo 1 Screw

- SGS 18 Years Merit Award – ISO 9001

- Taiwan Small & Medium Enterprise Innovation Award – KTX-Torpedo 1 Screw

Production On-line Service Login

Production On-line Service Login